-

Applied Materials’ New Vistara™ Wafer Manufacturing Platform Helps Customers Tackle Chipmaking Challenges

ソース: Nasdaq GlobeNewswire / 11 7 2023 04:30:41 America/Los_Angeles

- Flexibility: Applied’s most significant new platform in more than a decade hosts an unprecedented wide variety of chamber types, sizes and configurations, from Applied and partners

- Intelligence: Massive onboard sensor data feeds Applied’s AIx™ software platform to accelerate R&D, speed time to market, and maximize output and yield in high-volume production

- Sustainability: First platform purpose-designed to help customers meet sustainability goals by reducing fab energy, chemicals and construction materials consumption

SANTA CLARA, Calif., July 11, 2023 (GLOBE NEWSWIRE) -- Applied Materials, Inc. today introduced Vistara™, Applied’s most significant wafer manufacturing platform innovation in more than a decade, designed to provide chipmakers with the flexibility, intelligence and sustainability needed to tackle growing chipmaking challenges.

The Vistara platform builds upon the company’s long history of leadership in semiconductor manufacturing platforms that include Endura®, Producer®, Centura® and Centris®, found in fabs around the world and used in the production of virtually every chip made. Vistara was developed over more than four years by hundreds of engineers from across Applied’s hardware, software, process technology and ecoefficiency design teams.

“Like its predecessors, Vistara is designed to be a trusted platform for many years of customer innovation, reliability and productivity,” said Dr. Prabu Raja, President of the Semiconductor Products Group at Applied Materials. “Vistara is being launched at an opportune time when the semiconductor industry needs unique solutions to address growing chipmaking challenges related to complexity, cost, cadence and carbon emissions.”

Flexibility

Vistara’s unmatched flexibility helps chipmakers solve the growing complexity challenges of advanced chipmaking. The Vistara platform is able to use an unprecedented wide variety of chamber types, sizes and configurations from Applied and its partners. It can be configured with four or six wafer batch load ports and from as few as four to as many as 12 process chambers to address a wide variety of workloads. The Vistara platform accepts both smaller chambers used in processes like atomic layer deposition and chemical vapor deposition as well as larger chambers used in processes such as epitaxy and etching. Applied and its customers can combine these chambers to develop IMS™ (Integrated Materials Solution®) recipes whereby a number of sequential wafer manufacturing process steps are completed in the same system, under vacuum. The flexibility of Vistara gives chipmakers IMS technology combinations that were never possible before, enabling them to deliver innovative transistors, memories and wiring, improve performance and power, and protect against yield-killing particles and defects.

Intelligence

The Vistara platform’s intelligence helps customers address growing cadence and cost challenges by accelerating time to market and maximizing productivity and yield in high-volume manufacturing. Vistara platforms are configured with thousands of sensors that feed massive, real-time data to Applied’s AIx™ software platform which offers applications spanning R&D, process transfer and ramp, and high-volume manufacturing. Actionable data from thousands of process variables enables engineers to use the power of machine learning and AI to accelerate recipes that can result in the best chip performance and power and widest process windows. Intelligence is incorporated throughout the platform including in the factory interface module where load locks are intelligently controlled to optimize pump and vent times, helping chipmakers reduce particles and defects to maximize yields. Platform robots are automatically calibrated to reduce start-up times by as much as 75 percent. In production, the Vistara platform continuously monitors and calibrates its components to minimize manual intervention, maximize uptime and predict maintenance needs.

Sustainability

The increase in semiconductor process complexity and steps adds to the energy and materials needed to produce each wafer. Vistara is the first platform purpose-built to advance Applied’s “3x30” initiative designed to achieve 30-percent reductions in equivalent energy use, the impact of chemical use, and cleanroom floorspace requirements, all by 2030. Engineers completely redesigned the Vistara platform’s gas panels to reduce the equivalent energy consumption by more than 50 percent compared to the previous design and optimized the way the platform uses energy-intensive sub-fab components including pumps, heat exchangers and chillers. These improvements can lower platform energy consumption by as much as 35 percent compared to previous platforms, helping chipmakers reduce their Scope 1 and Scope 2 emissions. Vistara also reduces the cleanroom footprint of a system by as much as 30 percent. Such savings help customers generate more wafers in smaller facilities, reducing the use of carbon-intensive construction materials such as concrete and steel, a 30-percent reduction of which can potentially save 1 million metric tons of carbon for every 100K wafer-starts-per-month (WSPM) fab built.

Introducing EcoTwin™ Software

Applied is also introducing EcoTwin eco-efficiency software, available first with the Vistara platform. EcoTwin software uses sensor data to help engineers monitor the real-time energy and chemical consumption of chambers, systems and subfab components. Process engineers can use the EcoTwin dashboard to compare the carbon impact of alternative chemicals, recipes and production techniques to continuously improve sustainability over the life of a node and track and report on progress toward sustainability goals.

Availability

The first Vistara platforms are being shipped to all leading memory customers for use in etch applications. Applied expects unit growth across all of its major platforms as the wafer fab equipment industry grows to support projected increases in worldwide semiconductor demand.

Forward-Looking Statements

This press release contains forward-looking statements, including those regarding anticipated benefits of our new products and technologies; expected growth and trends in our businesses and markets, industry outlooks and demand drivers, technology transitions, and other statements that are not historical facts. These statements and their underlying assumptions are subject to risks and uncertainties and are not guarantees of future performance. Factors that could cause actual results to differ materially from those expressed or implied by such statements include, without limitation: failure to realize anticipated benefits of our new products and technologies; the demand for semiconductors; customers’ technology and capacity requirements; the introduction of new and innovative technologies, and the timing of technology transitions; market acceptance of existing and newly developed products; the ability to obtain and protect intellectual property rights in technologies; our ability to ensure compliance with applicable environmental and other law, rules and regulations; and other risks and uncertainties described in our SEC filings, including our recent Forms 10-Q and 8-K. All forward-looking statements are based on management’s current estimates, projections and assumptions, and we assume no obligation to update them.About Applied Materials

Applied Materials, Inc. (Nasdaq: AMAT) is the leader in materials engineering solutions used to produce virtually every new chip and advanced display in the world. Our expertise in modifying materials at atomic levels and on an industrial scale enables customers to transform possibilities into reality. At Applied Materials, our innovations make possible a better future. Learn more at www.appliedmaterials.com.Contact:

Ricky Gradwohl (editorial/media) 408.235.4676

Michael Sullivan (financial community) 408.986.7977Photos accompanying this announcement are available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/ed4bc138-b3fa-49b4-aa89-287098178c94

https://www.globenewswire.com/NewsRoom/AttachmentNg/091698ec-368f-443d-819a-92a7d6036d5d

These photos are also available at Newscom, www.newscom.com, and via AP PhotoExpress.

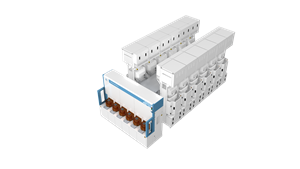

Applied Materials’ Vistara™ Wafer Manufacturing Platform

Developed over more than four years by hundreds of engineers, the new Vistara™ platform builds upon Applied Materials’ long history of leadership in semiconductor manufacturing platforms found in fabs around the world and used in the production of virtually every chip made.

Vistara™: A Platform Designed for Flexibility, Intelligence and Sustainability

Applied’s new Vistara™ wafer manufacturing platform is architected based on three pillars: flexibility, intelligence and sustainability. The platform is able to use an unprecedented wide variety of chamber types, sizes and configurations; leverages thousands of sensors that feed massive, real-time data to Applied’s AIˣ™ and EcoTwin™ software; and is purpose-built to help reduce the environmental impact of semiconductor manufacturing.